Pallet wrapping machine repair for different businesses

Wiki Article

Discover the Important Benefits of Utilizing a Pallet Wrapping Device in Your Storage Facility Workflow

In modern-day storage facility procedures, the adoption of pallet Wrapping equipments is ending up being significantly essential. These equipments simplify the product packaging process, boosting effectiveness while considerably lowering labor prices. They likewise guarantee constant Wrapping quality, which is crucial for item protection throughout transit. The advantages expand beyond just these aspects. There are additional advantages that can change storehouse monitoring, making it rewarding to check out even more.Enhanced Efficiency in Product Packaging Procedures

In the domain of logistics, efficiency stands as a vital purpose, and pallet Wrapping equipments greatly add to achieving this objective. These devices improve the product packaging procedure by automating the Wrapping of items, ensuring that items are safely packaged with minimal hands-on treatment. By decreasing the time invested in Wrapping, companies can enhance their operations, allowing for quicker turnaround times and enhanced throughput. Furthermore, pallet Wrapping equipments supply regular Tension and protection, enhancing the security of products during transport. This reliability reduces the risk of product damages, which can lead to costly delays. On the whole, the integration of pallet Wrapping machines right into product packaging procedures fosters a much more effective, trusted, and arranged method to logistics management.Considerable Labor Price Financial Savings

While firms venture to reduce operational expenses, the adoption of pallet Wrapping makers can bring about significant labor cost financial savings. By automating the Wrapping procedure, these equipments minimize the requirement for manual work, enabling employees to concentrate on more vital tasks. With the ability to cover pallets swiftly and continually, less workers are required to finish product packaging operations, resulting in lower pay-roll expenses. In addition, the machines enhance performance as they can operate continually, decreasing downtime related to manual Wrapping. pallet wrapping machine repair. This effectiveness translates to quicker turnaround times and enhanced total workflow. Training employees to operate these makers usually requires less time compared to training for hands-on Wrapping strategies, even more contributing to reduced labor prices in storehouse operations.Improved Product Protection During Transit

Consistent and Trusted Wrapping Quality

Pallet Wrapping machines provide trustworthy and regular Wrapping top quality, ensuring that every pallet is wrapped evenly despite operator experience. This harmony decreases the danger of damage during transportation, as correctly wrapped pallets maintain their stability. The devices apply an optimal quantity of stretch film, reducing waste and making certain that the tons is secured properly. Unlike guidebook Wrapping, which can differ considerably based on the employee's method, an automatic process guarantees that each pallet obtains the same anonymous level of security. This integrity not only enhances the security of products however additionally simplifies procedures, enabling for more helpful hints a much more efficient operations. Ultimately, the consistent Wrapping quality given by these devices leads to boosted client contentment and decreased costs connected with item loss.Boosted Storehouse Space Use

Effective warehouse area application is an essential consider maximizing procedures, and pallet Wrapping machines play a significant function in attaining this goal. By securely Wrapping pallets, these makers minimize the threat of item damage during storage space and transportation, enabling for more efficient stacking and storage methods. Improved stability implies that pallets can be filled greater without jeopardizing security, which makes best use of vertical space use. Additionally, the constant Wrapping process warranties consistent measurements, allowing much better organization and reliable use available room. This causes lowered aisle width requirements and permits even more item to be saved in the same area. Generally, utilizing a pallet Wrapping device boosts area effectiveness, adding to streamlined storage facility procedures and enhanced productivity.Regularly Asked Inquiries

What Kinds Of Products Can Be Wrapped Using a Pallet Wrapping Equipment?

Various items can be wrapped utilizing a pallet Wrapping equipment, including boxes, pallets of food, industrial items, and breakable products. The equipment fits diverse sizes and shapes, making certain safe packaging for effective transport and storage space.

Just how much Does a Pallet Wrapping Device Normally Price?

The expense of a pallet Wrapping machine normally ranges from $3,000 to $20,000, depending on functions and abilities. Factors such as automation level and brand name credibility can considerably affect the final rate.Can Pallet Wrapping Machines Be Integrated With Existing Storage Facility Systems?

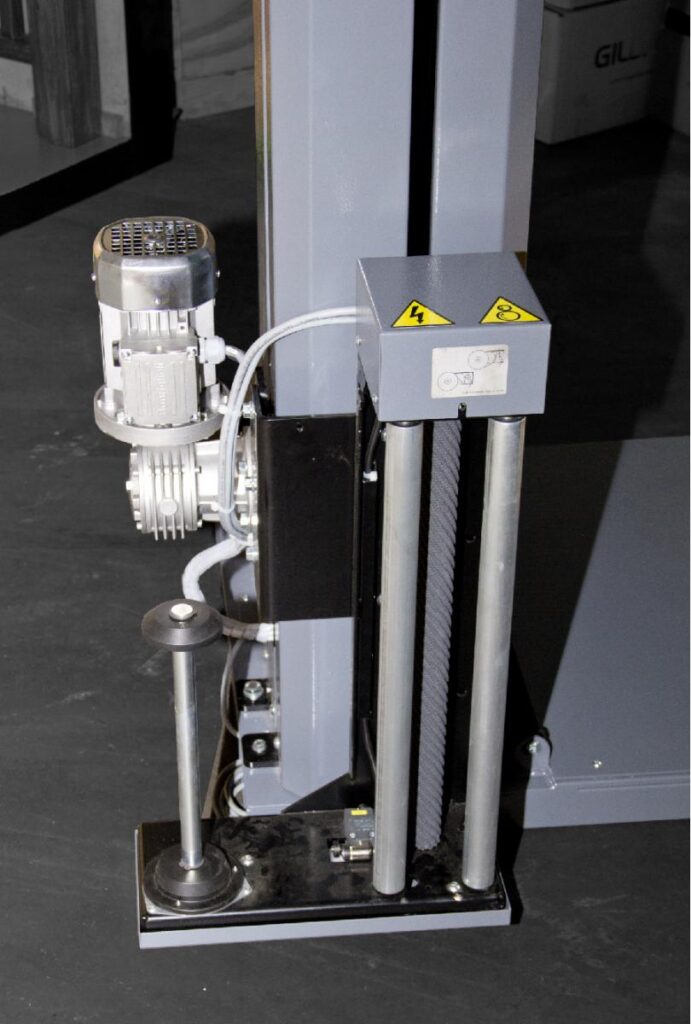

Pallet Wrapping makers can frequently be incorporated with existing stockroom systems, improving efficiency (pallet wrapping machine repair). This assimilation enables for structured procedures, boosted stock monitoring, and far better sychronisation with other automated procedures, ultimately optimizing informative post overall storage facility performanceWhat Is the Upkeep Need for Pallet Wrapping Machines?

The upkeep needs for pallet Wrapping equipments normally include routine evaluations, lubrication of moving components, and replacement of worn elements. Sticking to these practices assurances peak performance and longevity, lessening operational interruptions in storage facility setups.Are There Safety And Security Problems When Making Use Of Pallet Wrapping Machines?

When making use of pallet Wrapping devices consist of prospective injuries from moving parts, improper handling, and poor training, safety and security problems - pallet wrapping machine repair. Guaranteeing proper safeguards, normal upkeep, and employee education and learning can greatly minimize these threats in stockroom atmospheres

Report this wiki page